Design and Engineering Team

Unlike most small custom bike makers, Pursuit has multiple engineers and an in-house test lab. Jared Nelson, one of our founding partners, is a mechanical engineer with a Ph.D. who specializes in carbon fiber. He is responsible for all our laminate designs, test design, and analysis. We also have a design engineer, Jeff Wyatt, who does product design, tooling, and CAD design work. Finally, Luke Middelstadt is our production engineer. That’s a lot of engineering horsepower for a small company like Pursuit.

Carl Strong, General Manager

Since 1993, Carl has manufactured frames of all types and materials for thousands of Strong Frames clients.

Carl uses his years of experience designing frames for clients to design the general sizing and geometries of the Pursuit product line.

Jared Nelson PhD, Composites Engineer

Jared has worked in the bicycle industry in positions ranging from sales to manufacturing at companies like Spinergy and Seven Cycles. Later an opportunity to focus on production management and manufacturing engineering led him to MacLean Quality Composites, where he worked on growing the composite tubing sector. He completed his Ph.D. in Mechanical Engineering from Montana State University, where he studied the effects of typical composites manufacturing defects.

Luke Middelstadt, Manufacturing Engineer

Luke is a Mechanical Engineer that started with Pursuit as an intern while attending college at Montana State University. Luke heads up the manufacturing operations and makes sure all our bikes are meeting our quality and design goals.

Jeff Wyatt, Design Engineer

Jeff is a Bozeman-based design engineer and lifelong cyclist. He’s demonstrated a natural understanding of Pursuit’s goals and aesthetic right from the start. Jeff is the founder of Pinion Engineering, Jeff and his team are responsible for industrial design, modeling, renderings and mold design.

We thought a lot about how to master a complex, unrestricted material like carbon fiber while simultaneously paying tribute to the nostalgia that continues to inspire us.

We thought about breakthroughs, both personal and systemic. We thought about the birth of mountain biking, road racing, criteriums. We thought about epic days on steep climbs and athletes like Hinault, LeMond and Induráin.

The simpler the better, we decided. Why? Because we’re committed to building a pure, top-performing bike that lasts day in and day out.

Our Design Engineer combines that inspiration with a passion for design, engineering, manufacturing, and CAD, and develops the blueprint for the overall physical design.

Hand Drawn Initial Design Concepts

Everything starts with pen and paper. Carl and Jeff, Pursuit’s design engineer, start with a list of criteria, discuss each feature, and sketch various options until they land on an overall style that makes them happy.

3D Model

Once the general criteria and aesthetics are developed by hand, Jeff builds the model in the computer. This model will be the basis for all development as the process moves forward.

Photorealistic Rendering

The renderings allow us to see how light and shadow will interplay with the overall aesthetic of the design.

Checking Specs and Fit

Prior to committing to molds, a 3D model is produced and all specs are confirmed. Then we assemble the model to ensure that all parts fit as expected and there are adequate clearances.

Laminate and Ply Design

Jared designs the laminate schedule, which determines the characteristics of each part. From there, we develop the ply shapes and digitize the ply design for cutting.

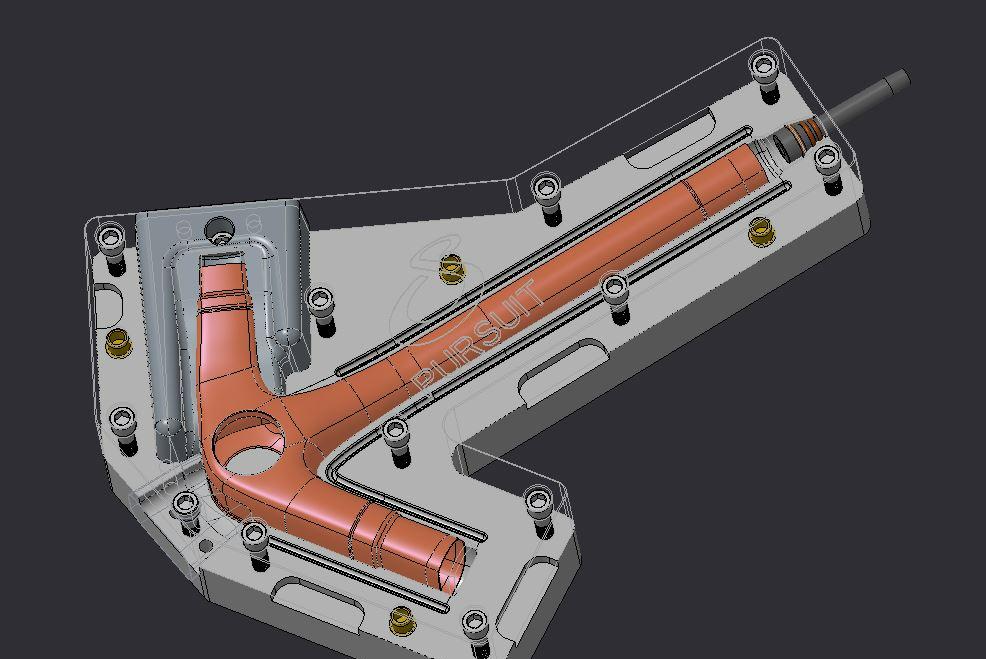

Create CAD Designs for Molds

The final step is creating the CAD design for each mold used to create the parts. Once these designs are complete, we send them to our partner for manufacture.